Hydrodewaxing

Catalytic dewaxing

reference information

Сatalytic dewaxing process (hydrodewaxing) is intended for improvement of flow indexes of various hydrocarbon feed at low temperatures. It is applied for decreasing pour point of basic components of lubricating oils and middle distillates, diesel fuel cloud point and aviation fuel freeze point. These properties determine behavior of the specified products at low temperatures.

At low temperatures flow indexes depend heavily on concentration of normal and close to normal paraffins in oil components and fuels. With rise of paraffin concentration in hydrocarbon feed its pour point, cloud point and freeze point increase. Temperature flow indexes go down with paraffin molecular weight increase (length of chains). Hydrodewaxing process improves these indexes using selective cracking of long-chain normal and close to normal paraffins. At the same time deep hydrotreatment of kerosene and diesel fuel with sulfur and nitrogen removal as well as saturation of aromatic compounds proceed.

Key features of hydrodewaxing process are the following:

- low pour point of products (below -50 °C);

- high stability of products;

- good cetane properties of products;

- constant quality of products during all cycle;

- minimum viscosity decrease in comparison with other dewaxing processes;

- flexibility that allows producing oil components and processing distillates at the same unit.

Hydrodewaxing catalysts

In catalytic dewaxing process for selective hydrocracking of long-chain paraffins, bifunctional catalysts based on alumina or crystalline aluminosilicate with pore size of 4-10 m-10 are used.. As a rule, the first stage of process includes feed hydrotreatment during reactions of olefins saturation, desulfurization and denitrogenation. Pretreatment protects catalyst and reduces organic sulfur and nitrogen content in the feed that improves hydrocracking indexes.

Different companies developed catalysts based on erionite, mordenite and ZSM-5, they are offered for industrial production of jet and diesel fuels.

In the USA Gulf Research and Devel Company created H-mordenit catalyst with 1% of palladium and 0,5% of titan content for hydrodewaxing of fuel oils, distillate fuel fractions, by means of which under the following process conditions: temperature = 300 °C, pressure = 0.7 MPa, feed WHSV = 1.0 h-1, hydrogen circulation ratio = 1780 nm3/m3, - low-pour-point fuels with pour point of minus 55 °C can be produced.

Texako Inс. developed dealuminated H-mordenit, used for oil straight-run distillates with pour point of 4-10°С to produce from them dewaxed gasoil with pour point of minus 18-60°С over the given catalyst under the following process conditions: temperature = 230-400°С, pressure = 1.4-10.5 МPа, feed WHSV= 0.25-5 h-1 . Hydrogen circulation ratio is 890-1800 nm3/m3.

For straight-run gasoil hydrodewaxing, distillated within the range of 204-400°С and having pour point of 9-13°С, Mobil Oil Со. developed Zn(Cd) catalyst ZSM-5 with 2 % content of palladium (platinum) and catalyst HZSM-5 with 0.5-5 % content of nickel, platinum, palladium, over which boiler fuel with pour point of minus 18°С (yield= 83-88 %) can be produced under the following process conditions: temperature = 307-371°С, pressure = 2.8-3.5 МPа, feed WHSV = 1-З h-1, hydrogen circulation ratio= 230-890 nm3/m3.

Depending on catalyst and initial feed, catalytic dewaxing process is carried out at temperature of 200-480 °C, pressure of 0.7 – 7.5 MPa, feed WHSV of 0.2-10 h-1, with H2/HC ratio = 178-1800 nm3/m3. Nowadays the most effective catalysts in activity and operation stability are considered the ones based on zeolite of ZSM type, which almost completely superseded the catalysts based on erionite and mordenite.

On the basis of HZSM-5 zeolite Mobil Oil Co. developed catalyst and catalytic dewaxing process of diesel fuel production from different types of feed under the common name “Mobil Distillate Dewaxing” (MDDW). The developed catalyst is tolerant to actions of sulfur and nitrogen compounds. The catalyst doesn't remove sulfur and nitrogen compounds, therefore the feed is subject to hydrotreating before or after hydrodewaxing. Values of MDDW process parameters depend on requirements for target product quality, type of feed, its boiling range, viscosity, and change in the following ranges: pressure of 2.8-6.0 MPa, feed WHSV of 1-2 h-1, hydrogen supply = 200-440 nm3/m3 of feed. With decreasing catalyst activity, they rise temperature up to 400 °C for obtaining product with the required pour point. Then they carry out catalyst reactivation by hydrogen gas purging within 24 hours at temperature of 400-450 °C.

For the first time industrial check of MDDW catalyst and process was carried out at hydrodesulphurization unit at Mobil France Refinery in 1974. Run between reactivations was from 10 to 60 days.

Combined unit, including MDDW catalytic dewaxing and hydrotreatment [43], has been operating at SARNI Refinery of Gulf Oil company in Bertonico (Italy) since 1978. Capacity of the unit is 1910 m3 of gasoil per day.

Development of domestic distillates hydroprocessing catalysts for diesel fuel production with low pour point has begun in the 1970-s.

In 1982 on the basis of TsVM VNIINP zeolite the first hydrodewaxing catalyst SGK-1 was developed and introduced into the industry in OJSC Angarsk Petrochemical Company (earlier – PO Angarsknefteorgsintez), that allows producing high-quality low-pour-point aviation, diesel fuels from the corresponding hydrotreated kerosene and diesel fractions of primary or secondary origin. SGK-1 catalyst contains 12.5-27.7 % of alumina, 2.0-5.0 % of magnesia, calcium oxide, boron oxide, 0.9-15.1 % of hydrogenating component and NTsVM zeolite. In activity and selectivity SGK-1 catalyst and its modification SGK-5 do not concede and in some parameters surpass the best foreign catalysts of this type.

Process scheme of catalytic dewaxing process

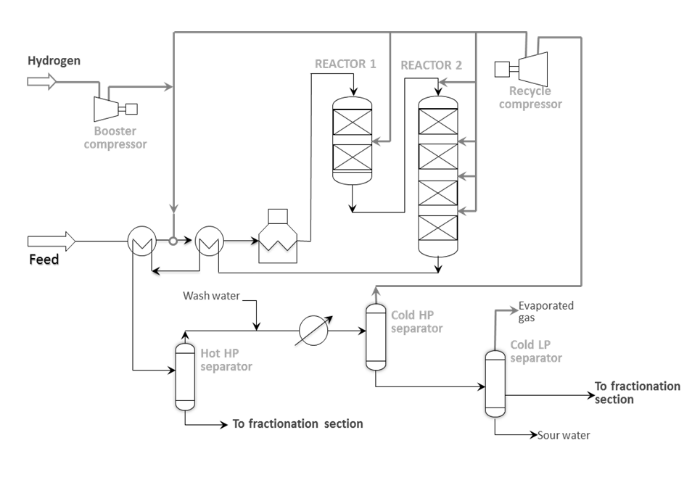

The simplified standard scheme of catalytic dewaxing process is shown in the figure below. Fresh feed is heated and mixed with hot recycle gas. Mixture is supplied to the first reactor where nitrogen and sulfur organic compounds are transformed producing ammonia and hydrogen sulfide. Reactions proceed with relatively low heat release. Then, pretreated stream is cooled by recycle gas from compressor and fed to the second reactor containing dewaxing catalyst. While feed is passing through dewaxing catalyst, long-chain n-paraffins are split into smaller molecules that increase feed flow indexes at low temperatures. Reactions are exothermic, continuous control of reactor temperature is required. Temperature is kept at minimum possible level required for obtaining necessary extent of molecules splitting.

Temperature in reactors is regulated by supply of cold recycle hydrogen gas between catalyst beds. Product from the second reactor is cooled in feed heat exchangers and fed to hot high-pressure (HP) separator where separation of liquid hydrocarbons from hydrogen gas vapors proceeds. Liquid product is directed to fractionation section, and hydrogen gas after additional cooling is fed to cold HP separator. For prevention of corrosion and ammonium salts deposition, before directing product for cooling, wash water is supplied. Steam from cold HP separator is mixed with make-up hydrogen and directed for blending with feed. Liquid hydrocarbons are fed to low-pressure (LP) separator.

Acid gas from LP separator is removed from the unit, and liquid product after separation of sour water is directed to fractionation section.

Information of this chapter is given exclusively for a reference purpose. You can find information about SIE Neftehim, LLC's products and services in Developments and Services chapters.