The product octane number has been increased at Isomalk-2 unit in Yaroslavl (Russia)

After the scheduled overhaul and configuration revamp, the light gasoline fractions isomerization unit Isomalk-2 with the feed capacity of 720 tons/year has been recommissioned at one of the largest refineries in Russia - Slavneft-YANOS PJSC. During the isomerization unit overhaul, the unit was revamped and the configuration of pentane fraction recovery in DIH column and its recycle to DIP column was implemented.

The revamp was performed on the basis of the Basic Engineering Design developed by SIE Neftehim, LLC in 2016.

The main feature of the process solutions adopted at this unit is that the isocomponent octane number has been increased from 89 to 91 RON without including new sections into the unit composition, without replacing the main process equipment, without replacing or additional loading the catalyst, and with the minimal changes of the existing equipment and utility lines.

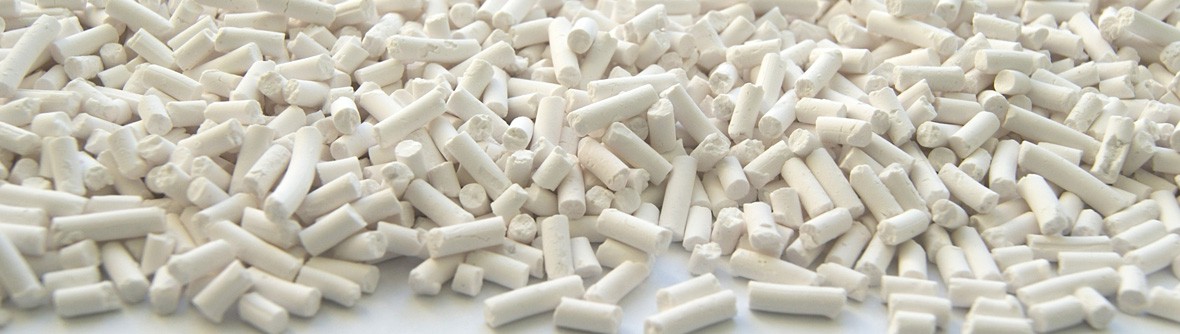

Isomalk-2 isomerization unit of Yaroslavl refinery was first commissioned in September 2011 according to the configuration with isopentane recovery section (DIP section) and low-branched hexanes recycle (DIH column section). The highly active oxide catalyst SI-2 was loaded into both reactors of the unit. From the moment of the initial start-up to the present day, the catalyst has been operating without regeneration (for 8 years) and showing high rates of activity and selectivity.

The unit start-up operations and commissioning were performed with the technical support of SIE Neftehim LLC’s experts.

We would like to thank the colleagues from SLAVNEFT-YANOS PJSC and the design institute OOO PROMHIMPROJECT that participated in the unit design documentation development, revamp, and start-up operations for the skilled collaborative work!