Chinese Sinopec has started up one of the most high-capacity isobutane production unit

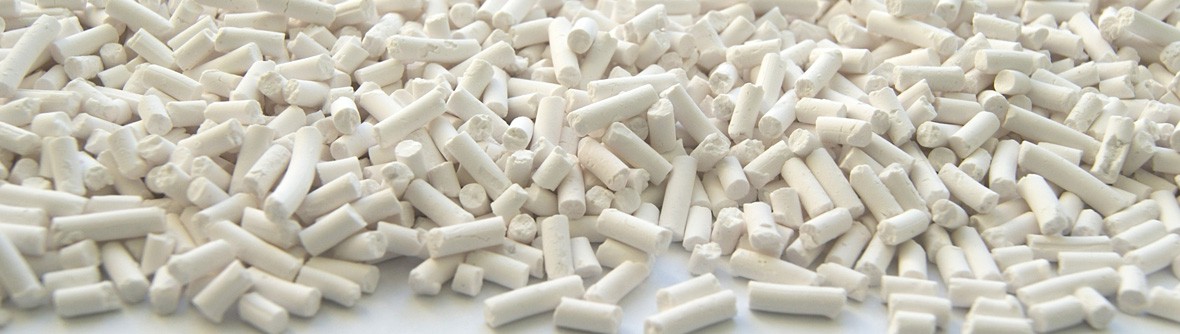

The n-butane isomerization unit has been designed in accordance with the requirements of SIE NEFTEHIM technology Isomalk-3 over the oxide (non-chlorinated) catalyst SI-3.

The n-butane isomerization section feed capacity is 480 KTA.

The start-up took place in September 2019 at Sinopec Jinling Petrochemical Co., Ltd., Nanjing, China.

This is already the fourth unit implemented exclusively according to the Russian technology Isomalk-3 over SI-3 catalyst of Russian manufacture.

The unit was designed by Sinopec Engineering Inc. Technical support during the whole process of the unit design, construction, and start-up was provided by SIE Neftehim together with the permanent partner - GTC-Beijing Technology Inc.

Sinopec is China’s second largest oil and gas company in terms of production output, and Sinopec Jinling Petrochemical Co., Ltd., Nanjing, China is one of China’s largest refineries with its own scientific base and colossal production capacities. Wikipedia/Sinopec

The rapid development of the chemical industry of the People's Republic of China in recent years has contributed to the advancement of the Russian development, including due to its advantages over isobutane production technologies using chlorinated catalysts.

The main advantage of Isomalk-3 is the absence of harmful wastes and effluents requiring disposal, low corrosivity, and long service life. More information about the advantages of Isomalk-3 can be found through the link: N-butane isomerization Isomalk-3

GTC- Beijing about the unit start-up: https://www.gtctech.com/isomalk-3-started-up-in-sinopec-jinling/