Activities

From the middle of the 1990-s the company’s researches and developments were concentrated on two directions – naphtha reforming and isomerization. However, as feed for these processes requires treatment in pre-hydrotreating and fractionation sections, both of these processes are included into the research area of the company.

Concentration of efforts on two basic directions has made it possible to take the functions not only of developers, but also of suppliers. Now SIE Neftehim, LLC is the recognized Licensor of catalysts and technologies for naphtha isomerization and reforming, it provides Basic Engineering of units, production and supply of catalysts, author's supervision over start-up operations, scientific and technical advisory services during operation.

In the recent years SIE Neftehim, LLC has considerably strengthened its research and experimental base and continues to expand its scientific activities:

- С5-С6-fractions isomerization – introduction and improvement of isomerization technology Isomalk-2 over strong-acid oxide catalyst SI-2, that has already been proved in the industry and obtained a widespread application

- С7- fraction isomerization – a new technology Isomalk-4 over oxide catalyst SI-4, that has no world analogues

- normal butane isomerization – a new technology Isomalk-3 over oxide catalyst SI-3

- xylene isomerization – development and introduction of new catalyst IK-112

- semi-regenerative reforming (SRR) of naphtha – introduction of new catalysts REF-125 and REF-130, developed on the basis of REF-25 catalyst, which has been proved and obtained widespread application in Russia, improved by addition of new stabilizing complexes in the structure

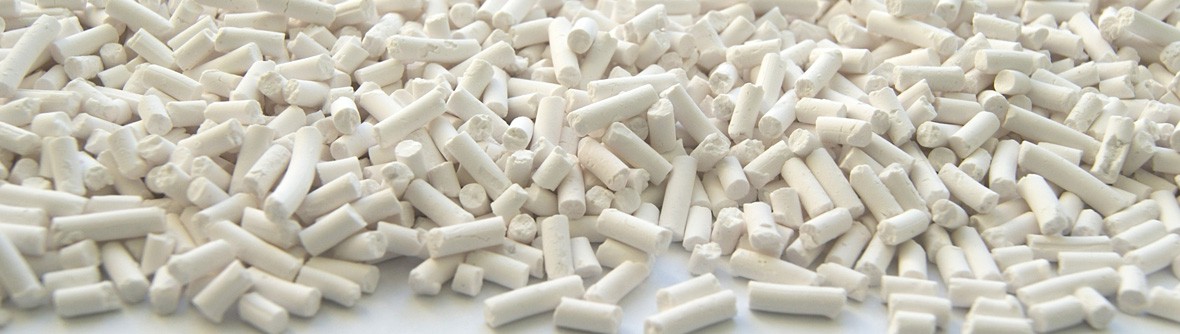

- continuous catalytic reforming (CRR) of naphtha – introduction of new reforming bead catalyst RC-12 for operation in the moving bed

- naphtha hydrotreating – production and supply of proved hydrotreating catalyst of DS series

- combined processing of wide naphtha – introduction of proprietary developments for improvement of existing production facilities and motor gasoline manufacture according to EURO-4 and EURO-5 standards