Combined Processing of Wide Naphtha IBP-180°С

Combined Processing of IBP-180°С fraction

The modern standards establish ever more severe requirements to wide naphtha processing technologies to produce motor gasoline more safe for the environment.

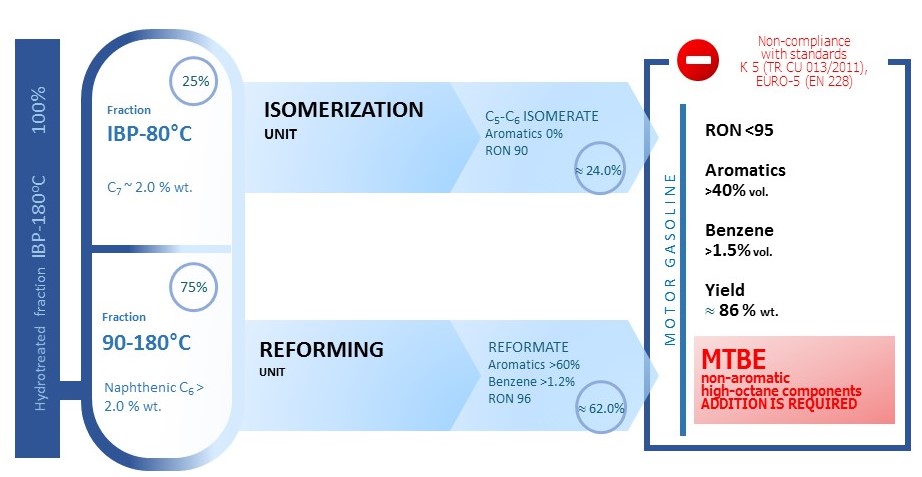

The most common motor gasoline production scheme both in Russia and in other countries is naphtha separation into feed of pentane-hexane fraction isomerization unit and reforming unit.

The main disadvantages of such gasoline production technology are:

- high benzene content in motor gasoline component (1.4-1.8 %);

- high content of aromatic hydrocarbons (42-44 %);

- yield of total catalyzate per initial feed is not more than 85-86 %.

To meet the modern requirements to benzene (<1 %) and aromatics (<35 %) contents in commercial motor gasolines, it is necessary to add large amounts of high-octane non-aromatic motor gasoline additives (ETBE, MTBE, alkylate). Nowadays, the motor gasoline that corresponds to K 5 standard (Technical Regulation of the Customs Union (TR CU) 013/2011 in Russia and Eurasian Economic Union) and EURO-5 standard (EN 228 in EU countries) is produced according to such technology. However, due to limitations of octane boosters content in motor gasolines in several countries, the motor gasoline production with 95 and 98 RON is limited.

There are technical solutions to decrease benzene content in reformate by fractionation and benzene concentrate recovery. However, such solution requires further processing of benzene fraction that leads to additional costs and significant decrease of the target product yield.

SIE Neftehim, LLC offers the production technologies proved via commercial and semi-commercial testing, which make it possible to minimize the application of additional expensive octane-boosting additives in motor gasoline production of ecological class K 5 (TR CU 013/2011) and EURO-5 (EN 228) and also enhance the gasoline production volume.

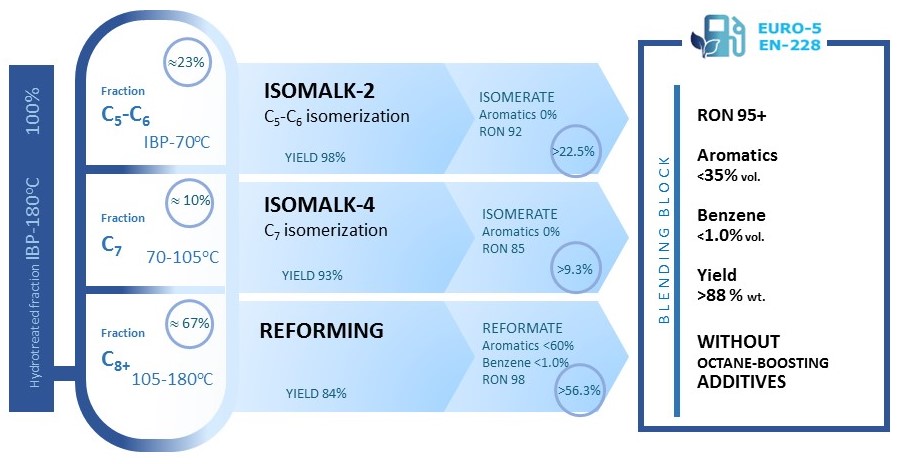

Wide Naphtha Combined Processing Technology

The main specific feature of the wide naphtha combined processing technology according to the scheme above is С7–hydrocarbons fraction recovery and its isomerization on a separate unit under Isomalk-4 technology developed by SIE Neftehim, LLC.

The involvement of С7 – fraction isomerization into the processing scheme allows:

- ensuring the guaranteed benzene content less than 1 vol. % and decreasing the aromatics content to 35%;

- ensuring effective operation of IBP-70°С fraction isomerization catalyst due to decrease of С7+ hydrocarbons content in the feed;

- enhancing the catalyst service cycle, yield, and octane number on reforming unit;

- increasing the commercial motor gasoline yield due to higher selectivity of С7-fraction isomerization process as compared to reforming.

Thanks to such wide naphtha processing scheme, K 5 (TR CU 013/2011) and EURO-5 (EN 228) requirements are met by compounding only iso-components and reformate that allows significantly decreasing costs for obtaining high-octane non-aromatic motor gasoline components.

To learn more about the possibility of wide naphtha combined processing technology application and motor gasoline production increasing at your production facility, you can contact us through Feedback Form. Please provide general information about your company and contact details in your email. Our experts will get in touch with you.

In 2014, the Russian Federation patent No. 2 524 213 «Method of producing high-octane motor gasoline» was granted (the patent assignees: SIE Neftehim, LLC and JSC Gazpromneft-ONPZ).

SIE Neftehim, LLC is also the developer and manufacturer of isomerization and reforming catalysts. The production plant is located in Nizhniy Novgorod, Russia.

Additional materials

For more details about the Isomalk-2 and Isomalk-4 technologies features, the features of the isomerization and reforming processes catalytic system included in the described technology for motor gasoline production, please refer to the Development section of our website or click the following links:

Naphtha reforming catalysts to produce motor gasoline and aromatic hydrocarbons

ISOPLAT – Effective production of motor gasoline with ultra-low content of aromatic hydrocarbons

SIE NEFTEHIM: Aiming the challenges of the future (НПП НЕФТЕХИМ: Работая на перспективу)

Review of new technology ISOPLAT to produce environmentally friendly high-octane gasoline components with ultra-low aromatics and benzene contents

Article in monthly trade magazine OilMarket (2019-No.2)

ISOMALK – Moving Forward Ahead of Global Trends (ИЗОМАЛК - опережая глобальные тренды)

Article in monthly trade magazine OilMarket (2018-No.1)

Article in monthly trade magazine Exposition Oil & Gas (2017-No.2) (in Russian only)

Full Publications List of SIE Neftehim