C7-fraction Isomerization ISOMALK-4

Heptane fraction isomerization technology to produce non-aromatic component of high-octane motor gasoline

Straight-run C7 hydrocarbon fraction boiling out in the range of 70-105°C consists mainly of n-heptane, 2-methylhexane, 3-methylhexane, and naphthenic hydrocarbons. The high content of unbranched paraffin hydrocarbons with low octane number (for n-heptane it is equal to zero) makes C7-fraction unsuitable as a component of modern motor gasolines. The share of iso-paraffin C7-hydrocarbons with high octane number in straight-run fractions is negligible.

Heptane fraction cannot be efficiently processed in existing С5-С6 fraction isomerization units, since the catalysts used in С5-С6 isomerization process are not selective towards С7-hydrocarbons. The level of hydrocracking reactions for heptanes in C5-С6-fraction isomerization process reaches 50%. In addition, heptanes have an inhibitory effect on the target reactions in C5-С6 isomerization process, which leads to a significant decrease in the entire process performances.

Sending С7-fraction to catalytic reforming unit feed is also not an optimal solution for gasoline production. Under the fixed-bed reforming process conditions, the rate of С7 paraffin hydrocracking reaction is significantly higher than the rate of dehydrocyclization reaction. Inclusion of С7 paraffin hydrocarbons in reforming feed leads to a decrease in reformate yield and octane number, a decrease in hydrogen production and a reduction in service cycle length.

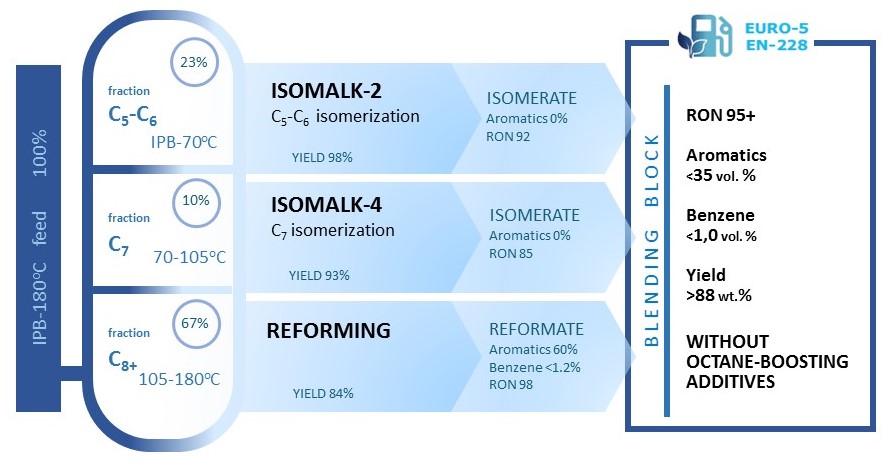

IBP-180°С straight-run gasoline fraction contains about 10-15% of heptane fraction, which during processing is either divided between the processes of С5-С6 isomerization and reforming, worsening the performances of these processes, or withdrawn separately without processing.

An effective option of heptane fraction processing is production of high-octane non-aromatic component via isomerization according to Isomalk-4 technology using SI-4 catalyst.

Introduction of Isomalk-4 technology improves efficiency of motor gasoline production at oil refineries thanks to:

1) Increase in the amount of a high-octane non-aromatic component involved in motor gasoline production and increase in motor gasoline yield per IBP-180°С fraction;

2) Possibility to meet strict standards for aromatics and benzene content in motor gasoline while reducing the amount of octane-boosting additives or completely abandoning their use;

3) Increase in reforming catalyst service life due to elimination of heptanes from reforming feed.

The below diagram represents principal diagram of gasoline production that includes Isomalk-4 technology:

The below table represents comparison of processing parameters without inclusion of С7-fraction isomerization process and with the use of Isomalk-4 technology:

| Parameter | Option 1 without С7-fraction isomerization |

Option 2 with С7-fraction isomerization according to Isomalk-4 technology |

|

Hydrotreated IBP-180°С fraction processing scheme to produce motor gasoline |

IPB-80°С to С5-С6 isomerization unit 90-180°С fraction to fixed-bed reforming unit |

IPB-70°С fraction to С5-С6 isomerization unit 70-105°С fraction to Isomalk-4 unit 105-180°С fraction to fixed-bed reforming unit |

|

Total gasoline pool yield, wt. % |

86-87 |

88-89 |

|

Total octane number of produced gasoline pool, RON |

94-95 |

95.0-95.5 |

|

Benzene content in gasoline pool, vol. |

1.3-1.5 |

0.8-0.9 |

|

Aromatics content in gasoline pool, vol. % |

41-43 |

34.0-34.5 |

|

Need of additives for gasoline to comply with К5 ТР ТС//EN-228 requirements |

it is required, |

is not required |

Sending heptane fraction to isomerization according to Isomalk-4 technology will allow for motor gasoline quality improvement and production volume increase.

Isomalk-4 technology catalytic system

Isomalk-4 technology is based on the unique catalyst SI-4 developed by SIE Neftehim.

Key features of SI-4 catalyst:

- high selectivity in С7-paraffin isomerization process;

- no need of reagent supply during operation;

- high stability and resistance to catalytic poisons;

- ensuring selective process of heptane isomerization at temperatures from 160°С;

- catalyst service life - 10 years;

- regeneration in-situ.

Commercial production of SI-4 catalyst is carried out at own catalyst factory in Nizhniy Novgorod, Russia. Each produced batch of catalyst undergoes multi-stage quality control.

Catalysts are produced and supplied by Neftehim with the provision of individual guarantees for the whole service life.

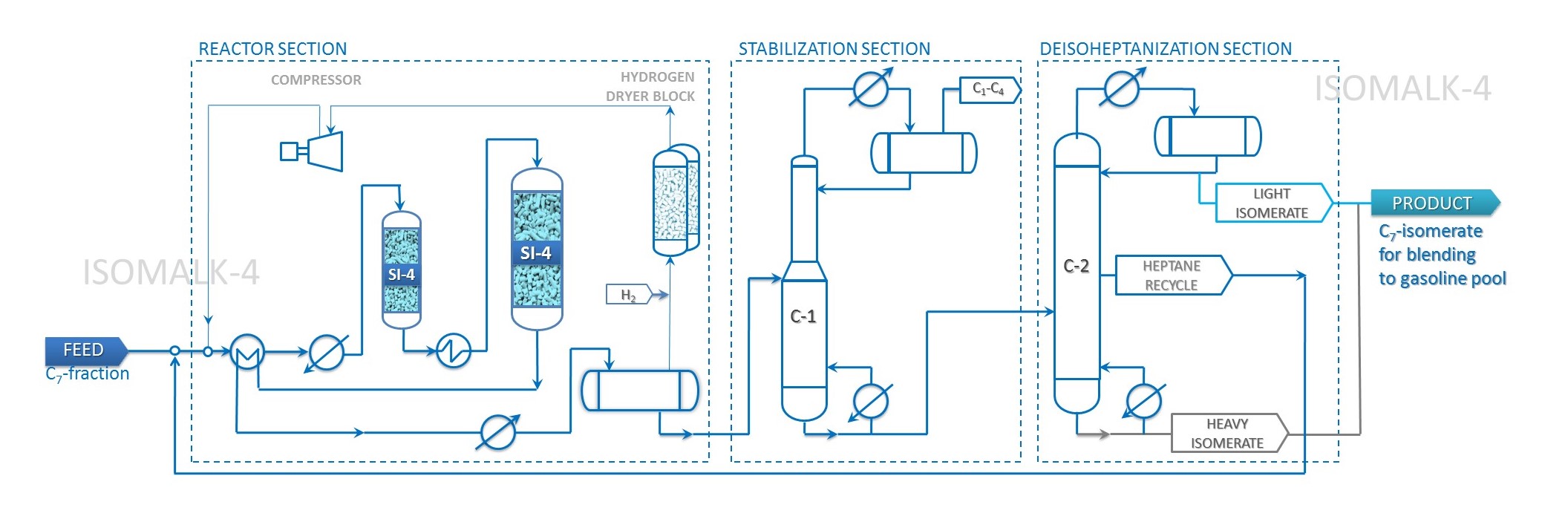

Isomalk-4 unit PFD

Hardware implementation of Isomalk-4 technology is close to that of Isomalk-2 conventional design. Configuration with unbranched heptane recycle makes it possible to produce 83-88 RON isomerate from low-octane heptane fraction (70-105°С fraction).

Isomalk-4 unit includes the following connected process sections of equipment:

— isomerization reactor section

(includes feed heater, reactors and gas drying block, compressor, separator and heat-exchanging equipment, it is possible to implement the process with “once-through” hydrogen supply);

— produced isomerate stabilization section

to remove hydrocarbon gas (С1-С4) and dissolved hydrogen residues from the product (consists of stabilization column and related equipment);

— deisoheptanization column section

serves to separate the target product – highly-branched heptane isomers, to separate the unconverted share of heptanes and send them to the reactor section feed as recycle in order to increase the product octane number

(consists of distillation column and related equipment).

Isomalk-4 unit does not require special adsorptive treatment of the feed from sulfur, nitrogen and water microimpurities. The necessary requirements for microimpurities content are achieved by typical hydrotreatment of the feed.

Heavy isomerate produced at the unit, which is concentrate of С7 naphthenic hydrocarbons, can be sent to the catalytic reforming unit feed. This will allow improving the operating performances of reforming unit and producing a higher-octane isomerate.

Special features of Isomalk-4 technology

- The reactors inlet temperature in Isomalk-4 process remains sufficiently low ~160°С during the whole service cycle, ensuring the required isomerization depth.

- Resistance to the catalytic poisons; a special preparation/additional treatment of the feed from sulfur and nitrogen impurities is not required.

- No costs for expensive reagents and hydrocarbon off gas treatment to remove chlorine impurities.

- SI-4 catalyst is regenerable (in-situ) and does not require unloading, reloading, additional loading during service life (10 years).

Technology commercialization

The implementation of Isomalk-4 technology does not require purchasing special licensed equipment. Simple and repeatedly elaborated design solutions allow accurately and quickly completing the retrofitting project with reference to the existing production facilities.

The process can be implemented both through the construction of new sections and through the revamp of old capacities of units for reforming, zeolite isomerization, chlorinated isomerization of pentane-hexane fractions.

SIE Neftehim provides full technical and consulting assistance for the project and guarantees the achievement of the specified product quality performances.

Isomalk-4 unit construction: key stages

The whole process from idea to the operating production facility can be divided into the following main stages:

- Inspection of existing production facility

- Feasibility study of Isomalk-4 technology implementation

- Making a decision on construction and kick-off meeting with all project participants

- Development of Basic Engineering Design – it contains all fundamental calculations and mandatory technology requirements

- Detailed Engineering Design – it is performed by a specialized engineering company involved by SIE Neftehim or a customer/investor

- Equipment order

- Construction

- Personnel training of the unit operation practices and skills

- Catalyst supply

- Pre-commissioning

- Start of the target product manufacturing

The experienced experts of SIE Neftehim guide the project at all stages, monitor the current operation of the unit and, if necessary, provide recommendations to improve the performance.

SIE Neftehim always promptly provides consulting and technical assistance in solving current production tasks.

![]() To start working with us, you can send us a letter through Feedback Form.

To start working with us, you can send us a letter through Feedback Form.

Please provide general information about your company and your contact details in the letter. Our experts will get in touch with you.

![]() Isomalk-4 technology and commercial isomerization catalyst SI-4 are protected by Russian and international patents.

Isomalk-4 technology and commercial isomerization catalyst SI-4 are protected by Russian and international patents.

"Isomalk" and "SI" are registered trademarks. All rights reserved by SIE Neftehim, LLC solely.

SIE Neftehim, LLC patents and certificates

Additional materials to the article:

SIE NEFTEHIM: Aiming the challenges of the future

Article in monthly trade magazine OilMarket (2019-No.2)

ISOMALK - Moving Forward Ahead of Global Trends

Article in monthly trade magazine OilMarket (2018-No.1)

The best domestic solutions to improve the production efficiency of K5 class high-octane gasolines

Article in monthly trade magazine Exposition Oil & Gas (2017-No.2)

Full list of SIE Neftehim publications in print media

Read more:

Pentane-hexane fractions isomerization technology Isomalk-2

Combined processing of IBP-180°С

If you are interested in our materials and you want to enter into cooperation, please contact us through the Feedback Form or in any other way convenient for you. We will definitely get in touch with you.